Chemical resistance guide

An effective risk assessment should allow the user to select the appropriate personal protection against exposure to chemicals. To help users, SHIELD Scientific has developed one of the most comprehensive chemical resistance guides. Permeation and degradation gloves’ data can be selected either by CAS number, chemical name or product type (up to 3 gloves). The testing has been conducted by reputable testing laboratories (Respirex, Proqares & Centexbel). However, we would like to stress that all our gloves are disposable thin gauge gloves designed for light chemical protection.

GLOVES PERMEATION TEST

EN 16523-1:2015+A1:2018 (Determination of material resistance to permeation by chemicals – Part 1: permeation by liquid chemical under conditions of continuous contact) is the standard method in Europe for evaluating the chemical barrier performance of a PPE glove. This standard supersedes EN 374-3:2003.

As such one layer of the glove is placed between two chambers. The chemical being tested is placed on one side and a receiving fluid on the other. Breakthrough occurs when a permeation rate of 1µg/cm²/min is noted and is reported in minutes. Three samples are tested. Test results must be within 20% of the mean average of the three glove samples tested. The lowest score is reported. If not, gloves must be re-tested.

It should be noted that this test is a total immersion test and may not be representative of the environment, where disposable gloves are used. Here the emphasis is typically on incidental chemical exposure and the gloves will often be changed once a chemical splash has been observed.

It is also important to remember that the tests are done on unused gloves under laboratory conditions. In this respect the test temperature is 23°C (+/-1°C). The test methodology does not consider the stresses and strains to which disposable gloves are subjected whilst being worn. Similarly, a glove in-use is likely to be significantly warmer than an unused glove and the higher level of surface heat may accelerate chemical permeation. Read our article to learn more about the permeation resistance test for gloves.

GLOVES DEGRADATION TEST

An important additional consideration when assessing the chemical resistance properties of gloves is degradation.

According to ISO 374-1:2016+A1:2018, degradation relates to the “deleterious change in one or more properties of a protective glove material due to contact with a chemical. These changes include flaking, swelling, disintegration, embrittlement, discolouration, dimensions, appearance, hardening, softening etc”. Resistance to degradation is measured according to the standard ISO 374-4:2019 (ISO 374 Part 4: Determination of resistance to degradation by chemicals) and is now a compulsory test for PPE Category III certification of gloves offering protection to hazardous chemicals. Thus, this test must be carried out for each chemical detailed on the user instructions and whose "letter code" appears in the glove Type marking pictogram. Read our article to learn more about gloves resistance to degradation.

The degradation test is based on puncture resistance, whilst the glove is in continuous contact with the chemical. The amount of force that is required to puncture the glove sample with a stylus is recorded. At the end of the one-hour exposure period, degradation is expressed as a percentage change in puncture resistance between the unexposed and exposed test specimens. Degradation is referred to as DR (Degradation Rate) in the chemical resistance guide.

The importance of degradation in reducing the protective properties of gloves is particularly relevant to the more harmful chemicals.

UNDERSTAND THE GLOVES CHEMICAL RESISTANCE GUIDE RESULTS

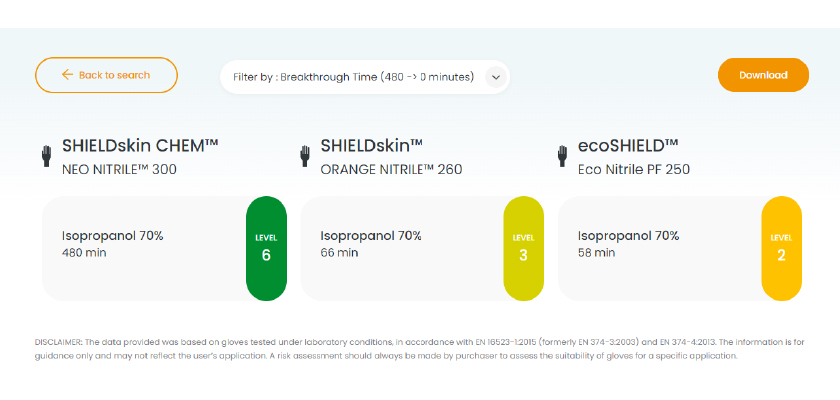

Once your request by CAS number, chemical name and/or glove (up to 3 gloves possible) have been done, you will obtain a list of results such as below:

In the above example:

- On the left: the CAS number and the name of the chemical.

- On the right side: the chemical breakthrough time expressed in minutes, the performance level of the glove and, if the chemical product is one of those tested as part of the determination of the Type of the glove (A, B or C), the degradation rate (DR) is also indicated.

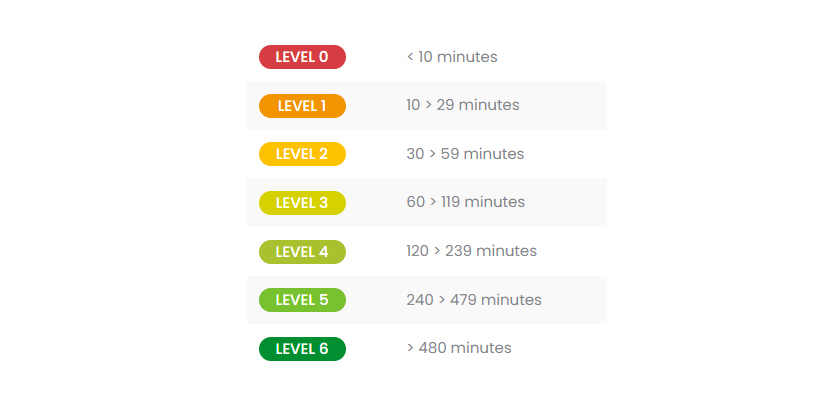

The breakthrough time expressed in minutes is converted into a performance levels' colour scale to ease the reading of results:

KEEP IN MIND: THE HIGHEST THE LEVEL (LEVEL 6), THE BETTER YOU WILL BE PROTECTED!

Whilst we have endeavoured to show most of the test data that is currently available, the chemical resistance guide is constantly being updated. Likewise, we have chosen not to include data that may be of a very specialist nature (e.g., testing against various chemotherapy drugs). Therefore, if you cannot find the chemical test data that you are seeking, please do not hesitate to contact us.